MPO (Multi-Fiber Push On) patch cords are essential for today’s high-density data center environments, supporting 40G/100G/400G/800G systems and structured cabling architectures. Compared with standard simplex or duplex patch cords, MPO products require far more complex engineering, tighter tolerances, and stricter testing procedures.

In this article, we walk through the complete MPO manufacturing process from a factory perspective, detailing how each step—from fiber preparation to 3D interferometry—is performed in real production environments.

If you want to see the manufacturing process of standard fiber optic patch cords, you can read our full guide here.

👉Fiber Optic Patch Cord Manufacturing Process: A Complete Guide from a Factory Perspective

TABLE OF CONTENTS

Why MPO Manufacturing Is More Complex

Before diving into the workflow, it’s important to understand why MPO production is so demanding:

• Multi-fiber ferrule technology

Unlike standard connectors that align a single fiber inside a ceramic ferrule, MPO connectors use MT ferrules housing 12, 16, 24, or even 32 fibers—all of which must be precisely aligned.

• Tighter geometric tolerances

Endface geometry (fiber height, angle, flatness) must be consistent across all fibers simultaneously.

• Polarity & gender variations

MPO requires strict control of:

✔ Polarity types (A, B, C)

✔ Gender (Male with pins / Female without pins)

• More advanced testing

MPO needs:

- Multi-channel IL/RL measurement

- Polarity verification

- Full 3D interferometer testing

- Multi-fiber endface inspection

This combination makes MPO production one of the most technical processes in passive fiber connectivity.

MPO Production Workflow Overview

A typical MPO production cycle includes:

- Cable cutting & pre-assembly

- Ribbonizing / fanout preparation

- Fiber stripping & cleaning

- MT ferrule gluing & fiber insertion

- Ferrule curing

- Multi-step MT polishing

- Advanced MPO testing

- Connector housing assembly & crimping

- Labeling & packaging

Step-by-Step MPO Manufacturing Process

1. Cable Cutting & Pre-Assembly

Production begins with automated cable cutting, ensuring precise length control and consistent batch performance.

Before fiber stripping, several connector components are pre-assembled onto the cable, including:

- Outer housing

- Boots

- Push-pull tabs

- Strain-relief components

Correct sequencing is essential—missing or reversed parts cause assembly delays and rework.

2. Ribbonizing or Fanout Preparation

Since MPO connectors terminate multiple fibers simultaneously, the fibers must be arranged and handled in a controlled ribbon structure.

Key objectives:

- Keep fiber order stable (1–12, 1–24, etc.)

- Ensure even tension across all fibers

- Avoid crossing, twisting, or stress points

For loose-tube cables, a fanout kit may be used to convert individual fibers into a ribbon-like structure.

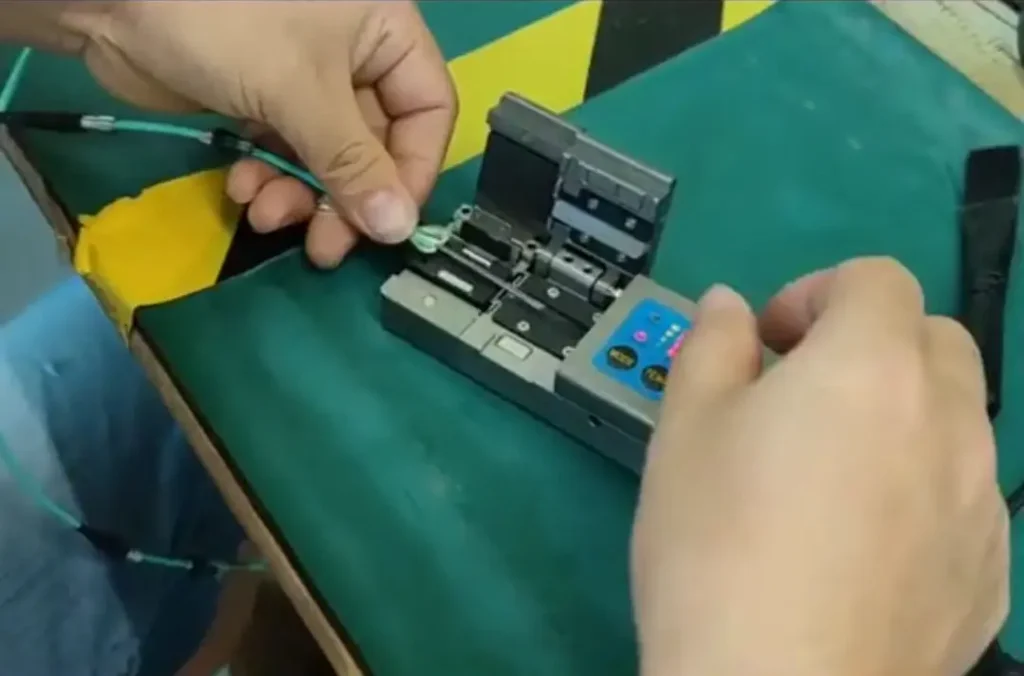

3. Fiber Stripping & Cleaning

This is one of the most technical steps of MPO manufacturing.

Fiber stripping

- Removing the outer jacket

- Trimming aramid yarn

- Stripping the fiber coating

- Cleaning the bare fiber with isopropyl alcohol

Glue Dispensing

- Epoxy must be dispensed into the MT ferrule with controlled volume

- Too much or too little adhesive affects bonding and polishing quality

Fiber Insertion

- All fibers must enter the micro-holes of the MT ferrule simultaneously

- Fiber alignment accuracy directly affects IL/RL performance

- Ferrule design tolerances are extremely tight (~1–2 μm)

Curing

- Ferrules are placed in temperature-controlled curing ovens

- Controlled curing prevents air bubbles and ensures full bonding strength

Poor curing or uneven epoxy distribution can result in fiber height differences, making the entire connector fail during polishing or testing.

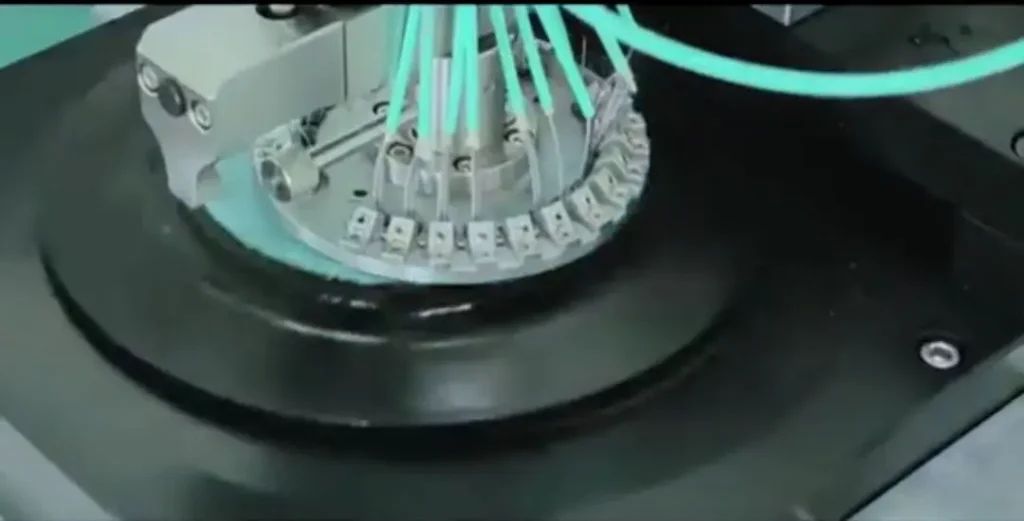

4. Multi-Step MT Ferrule Polishing

MPO polishing is significantly more difficult than single-fiber connectors because all fibers share one ferrule.

Polishing Stages

- Epoxy removal

- Coarse polishing

- Fine polishing

- Final mirror polishing

Why MPO polishing is challenging

- All fiber heights must fall within specification

- Scratches on any fiber cause entire connector failure

- MT polishing fixtures require precise pressure control

- Endface geometry affects IL/RL performance

Only after polishing is complete can the ferrule enter testing.

5. Advanced MPO Testing (Performed BEFORE final assembly)

5.1 Endface Visual Inspection

Technicians use microscopes to inspect:

- Scratches and pits

- Residual

- epoxyCracks or chips

- Fiber height consistency

- Cleanliness across all fibers

Any defect results in re-polishing or re-assembly.

5.2 Polarity Verification

Verify:

- Type A / B / C

- Correct fiber mapping (1–12 / 1–24)

- Alignment orientation

- Male/Female matching

Incorrect polarity requires re-routing the fiber or re-arranging the ribbon.

5.3 Multi-Channel IL/RL Testing

A dedicated MPO tester measures every channel:

- IL (Insertion Loss)

- RL (Return Loss)

Typical factory standards:

- MM IL ≤ 0.35 dB

- SM IL ≤ 0.35–0.60 dB

SM APC RL ≥ 60 dB

If even one fiber fails, the entire MPO ferrule must be reworked.

5.4 3D Interferometer Testing

This is the most advanced MPO quality control step.

3D interferometry measures:

- Fiber height (ΔH uniformity)

- Ferrule endface angle

- Apex offset

- Core protrusion/undercut

- Ferrule flatness

- Multi-fiber endface consistency

Connectors must meet IEC and GR-1435 geometry requirements before moving to final assembly.

6. Connector Housing Assembly & Crimping

Only connectors that pass all polishing and testing stages proceed to final assembly.

Housing Assembly

- Install outer housings

- Position latch and push-pull

- tabsEnsure correct mechanical fit

- Apply polarity markers

Crimping

- Fix fiber and aramid yarn to the connector body

- Provide strain relief

- Ensure long-term plug/unplug durability

Final assembly at this stage ensures no contamination occurs during polishing or testing.

7. Labeling, Packaging & Shipment

Finally, each MPO assembly undergoes:

- Polarity labels

- Gender marking

- Custom OEM/ODM labeling

- Protective packaging

- Batch sampling inspection

Consistent packaging ensures the connectors remain clean and protected during transport.

MPO Patch Cord FAQ

Why is MPO patch cord production more complex than standard patch cords?

Because MPO uses an MT ferrule with 12/16/24 fibers terminated simultaneously. This requires precise fiber alignment, multi-step polishing, strict polarity control, and advanced multi-channel IL/RL and 3D interferometer testing—far more demanding than single-fiber connectors.

What are the most critical factors affecting MPO performance?

The main determinants include fiber height uniformity, ferrule endface geometry, pin alignment (for male connectors), polishing quality, and accurate polarity mapping. Even a small deviation in any fiber can cause IL/RL failures.

How do factories ensure correct MPO polarity (A/B/C)?

During assembly, ribbon fiber mapping is positioned according to polarity requirements. Technicians verify polarity using polarity testers and visual alignment tools before final housing assembly. Incorrect polarity requires re-ribbonizing or re-terminating.

What tests are mandatory for high-quality MPO patch cords?

A complete factory must perform:

- Multi-channel IL/RL testing

- Polarity verification

- Endface visual inspection

- 3D interferometer testing (IEC / GR-1435 geometry)

These tests ensure stable performance for data center applications.

Final Thoughts

MPO manufacturing is a highly specialized process requiring precise equipment, skilled technicians, advanced polishing systems, and strict quality testing. From MT ferrule bonding to 3D geometry inspection, every step directly affects the connector’s final performance.

For data centers, cloud networks, HPC systems, and backbone infrastructures, choosing an experienced MPO manufacturer ensures stable and consistent performance across large production volumes.