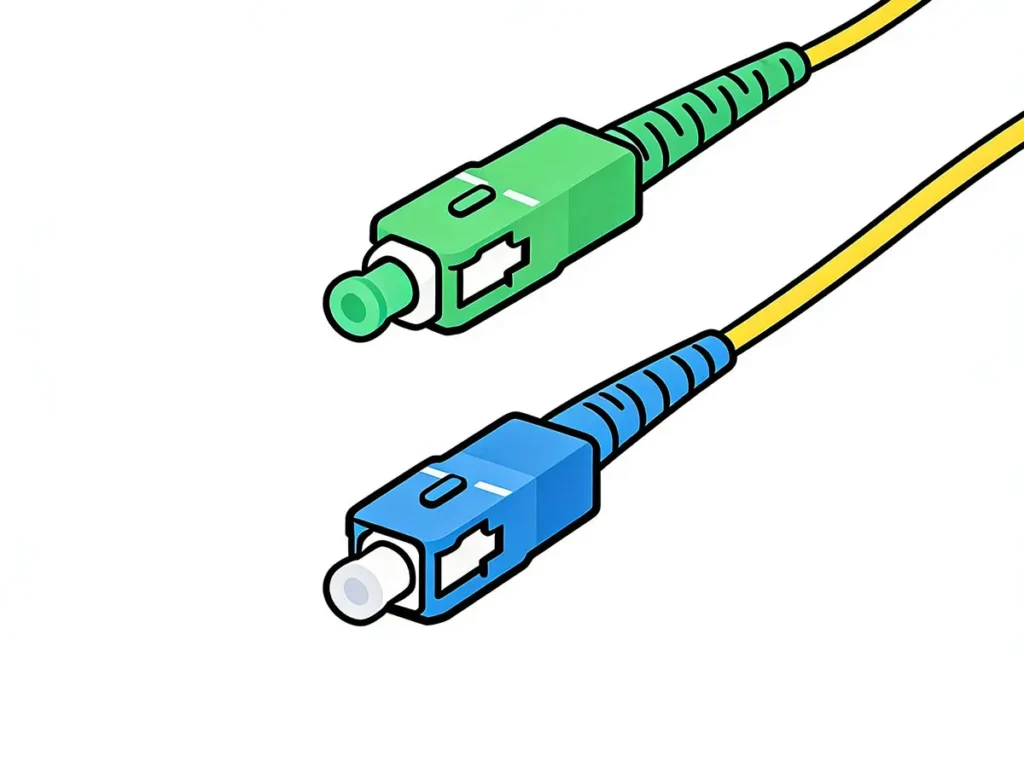

If you read older fiber-optic documents, you will often see the term PC (Physical Contact) used as a connector end-face type. But when you look at today’s products, catalogs, or even online stores, “PC” almost never appears as a standalone label. Instead, most connectors are marked UPC or APC, with blue and green colors becoming the industry standard.

So what exactly is PC? Why did it disappear from modern labeling? And how does it relate to UPC and APC?

As a fiber-optic manufacturer, we will explain PC from a practical, production-based perspective — and clarify why PC was eventually replaced by UPC.

TABLE OF CONTENTS

What PC Originally Meant

PC stands for Physical Contact. This polishing style was created to solve the biggest problem of the early flat-polished (Flat/FP) connectors: high insertion loss and unstable performance caused by an air gap between the two fiber cores.

With PC polishing, the ferrule end face is slightly curved so that the two fibers physically touch each other when connected. This greatly reduces the air gap and improves insertion loss performance.

In the 1990s and early 2000s, PC was the dominant polishing type for almost all single-mode connectors. It marked a major step forward in fiber-optic connector evolution.

PC vs UPC: What Changed?

As fiber networks demanded lower loss and higher return loss, the basic PC structure was further optimized. Manufacturing equipment improved, polishing films became more precise, and stricter inspection standards were adopted. These upgrades resulted in a more refined version of PC — called UPC (Ultra Physical Contact).

UPC still uses the same general dome-shaped geometry as PC, but with:

- A smoother surface finish

- Tighter radius control

- More precise polishing steps

This gives UPC better optical performance, especially in terms of return loss.

- PC: Around –30 dB to –40 dB

- UPC: Around –50 dB to –55 dB

Because UPC is essentially a higher-grade evolution of PC, most factories stopped marking “PC” on products. Instead, UPC became the new standard for blue single-mode connectors.

This is why most of the industry visually associates blue = UPC.

Why PC Is Rarely Seen Today

Although PC technically still exists as a concept, it is no longer used as a market label. Here are the main reasons:

a. The industry decided on standardized color coding

Modern fiber networks require clear, unmistakable identification.

Color codes help installers work faster and avoid errors:

- Blue = UPC

- Green = APC (Angled Physical Contact)

- Beige / Aqua, etc. = Multimode variations

There was no dedicated color for PC, which made it impractical for large-scale manufacturing and field installation.

b. UPC performance is better and cost-effective

UPC polishing provides:

- Higher return loss

- More stable mass-production consistency

- Better surface quality under interferometer inspection

And the cost difference today is minimal. So manufacturers naturally favored the better-performing option.

c. Customers and distributors expect UPC as the default

As market awareness grew, “PC” disappeared not because it was unusable, but because:

- Distributors order UPC by default

- Installers expect UPC in all blue connectors

- Data sheets, OEM catalogs, and standards reference UPC

Essentially, PC was replaced due to market alignment and user expectation, not just technical factors.

So Is PC Still Used Internally?

Yes — but mostly as a classification term, not a product label.

Factories still use “PC geometry” to describe the general dome-shaped polishing category (compared to APC’s 8° angle).

Inside production documents, you will still see references to:

- PC geometry radius

- PC polishing steps

- PC interferometer parameters

But the final product is almost always labeled “UPC” when it exits the factory.

So PC is still part of the manufacturing language, but not part of modern sales terminology.

Understanding the Relationship: PC, UPC, and APC

Here is the simplest way to understand the evolution:

- PC – the original physical-contact end face

- UPC – an upgraded, more precise version of PC

- APC – an angled version of PC (8° polish), giving the best return loss

All three share the same basic structure and polishing principle — physical contact — but UPC/APC are modern, improved forms that replaced early PC connectors.

So when you see “UPC” or “APC,” they are not completely different inventions; they are refinements built on top of the original PC concept.

Why Many People Still Mention PC Today

Many older books, tutorials, and certifications still reference PC because:

- It is historically significant

- It helps explain the evolution of connector polishing

- Many beginners see “UPC/APC” and wonder what the “P” stands for

In reality, the term PC is still useful for teaching, but modern networks almost never purchase connectors labeled simply as “PC.”

Conclusion: PC Still Matters, But UPC Took Its Place

PC is the foundation of modern fiber-optic connector polishing. Without it, UPC and APC would not exist. But as technology improved, UPC replaced PC as the standard “straight-polish” connector type used in today’s FTTH networks, data centers, and telecom systems.

This is why you rarely see “PC” in catalogs — the entire market, from factories to installers, shifted to UPC for performance, stability, and clarity.

If you want a deeper comparison between UPC and APC, you can check our detailed article here:

“Fiber Optic APC vs UPC – What’s the Real Difference?”