Fiber optic technology has become the backbone of modern communication, powering everything from high-speed internet to cloud data centers and 5G networks. At the heart of this technology lies a small but critical component—the fiber optic connector.

These connectors provide a fast, precise, and reliable way to join optical fibers, ensuring minimal signal loss and consistent performance. In this guide, we’ll take a closer look at fiber optic connectors, their types, designs, and key considerations to help you better understand this essential element of fiber optic networks.

TABLE OF CONTENTS

What is a Fiber Optic Connector?

A fiber optic connector is a mechanical device used to join two optical fibers together, enabling light signals to pass with minimal loss. Unlike traditional copper connectors, fiber connectors must be designed with extreme precision to ensure perfect alignment of the fiber cores, typically within a tolerance of a few microns.

The primary function of a fiber optic connector is to allow quick, reliable, and repeatable connections between fibers or between fibers and active equipment such as transceivers. In high-performance networks, the quality of a connector directly impacts signal integrity, insertion loss, and return loss.

Fiber optic connectors are widely used across multiple industries:

- Telecommunications and FTTx – enabling last-mile fiber deployment.

- Data Centers – supporting high-density connections for servers and switches.

- Broadcast and CATV – ensuring stable transmission for audio and video signals.

- Industrial and Medical Applications – where precise optical transmission is essential.

Simply put, fiber optic connectors are the “gateways” that allow light to travel seamlessly between fibers, forming the backbone of modern high-speed communication systems.

Looking for reliable fiber optic connectors supplier? Our factory manufactures high-quality fiber connectors, ensuring stable performance. Learn more about our Fiber Optic Connector.

Classification by Connector Types

Over the years, many types of fiber optic connectors have been developed to meet different requirements for size, performance, and application. Below are the most common connector types used today:

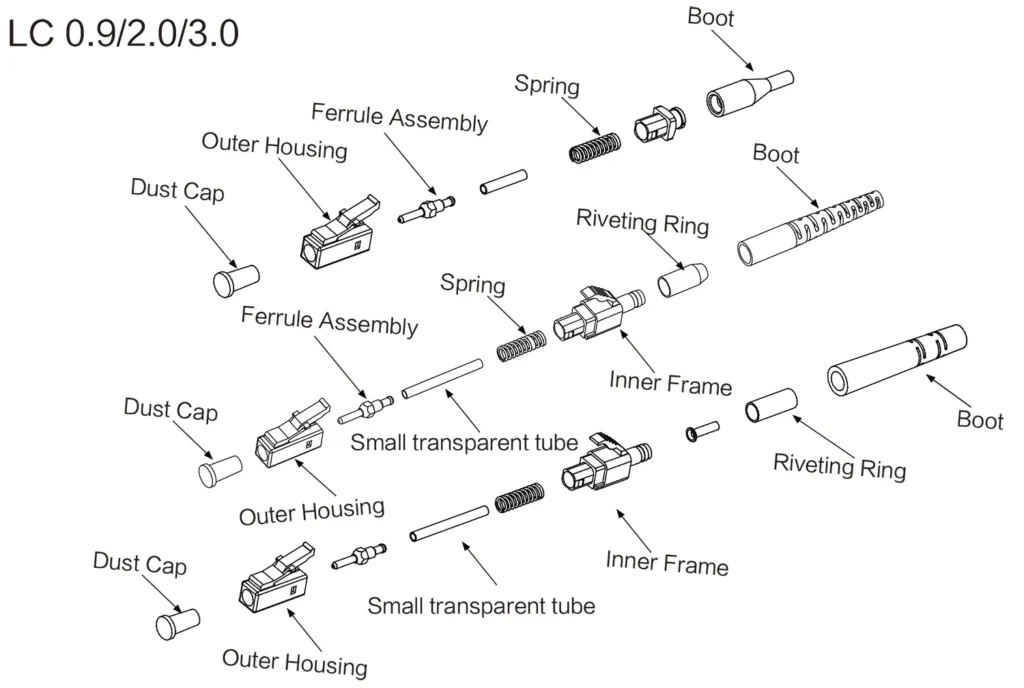

LC (Lucent Connector)

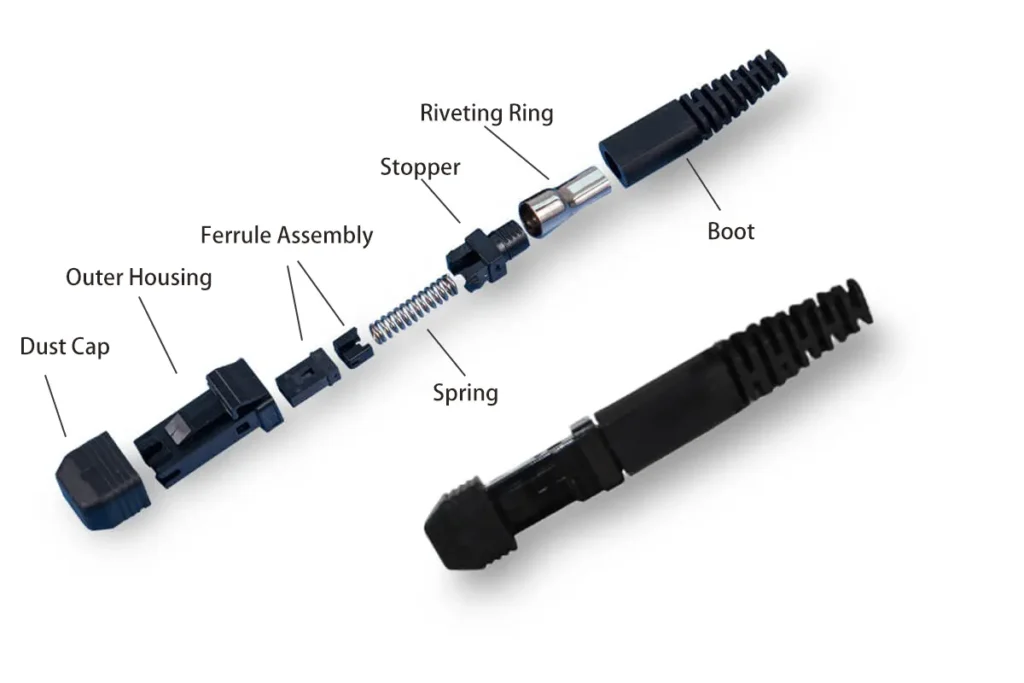

Figure1-1: 0.9/2.0/3.0mm LC Fiber Optic Connector exploded view

As shown in Figure 1-1, the structure of an LC connector can vary depending on the diameter of the optical fiber pigtail. The figure illustrates a typical example of LC connector components.

The LC connector is one of the most popular in modern networks due to its small form factor. It uses a 1.25 mm ferrule, making it ideal for high-density applications such as data centers and telecommunication racks. Its push-pull mechanism provides easy operation, and LC connectors are commonly found in duplex form for bi-directional transmission.

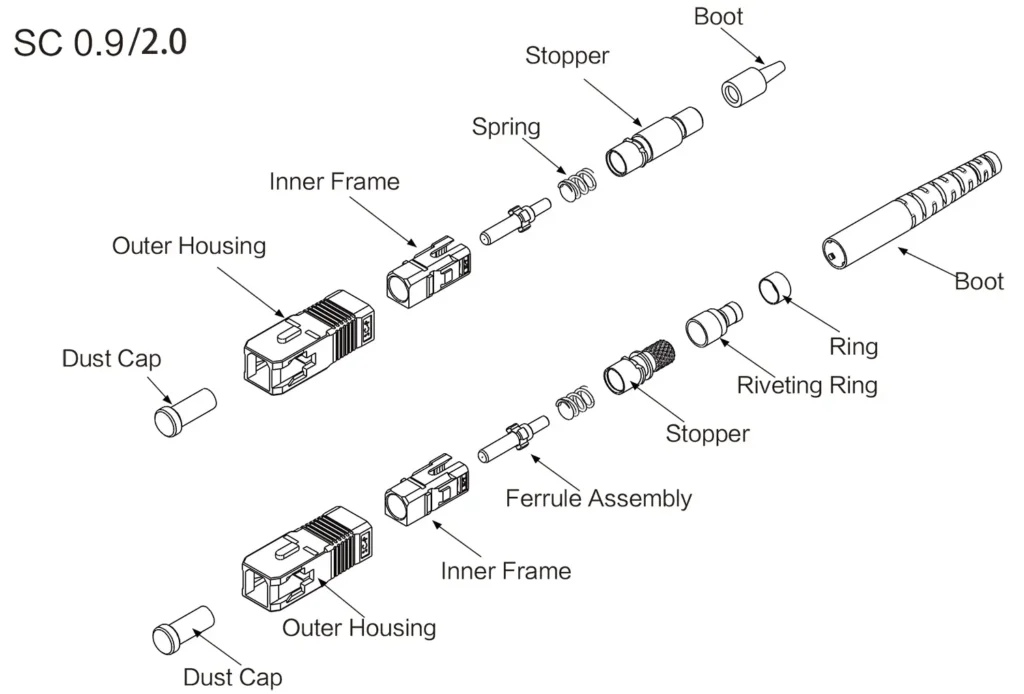

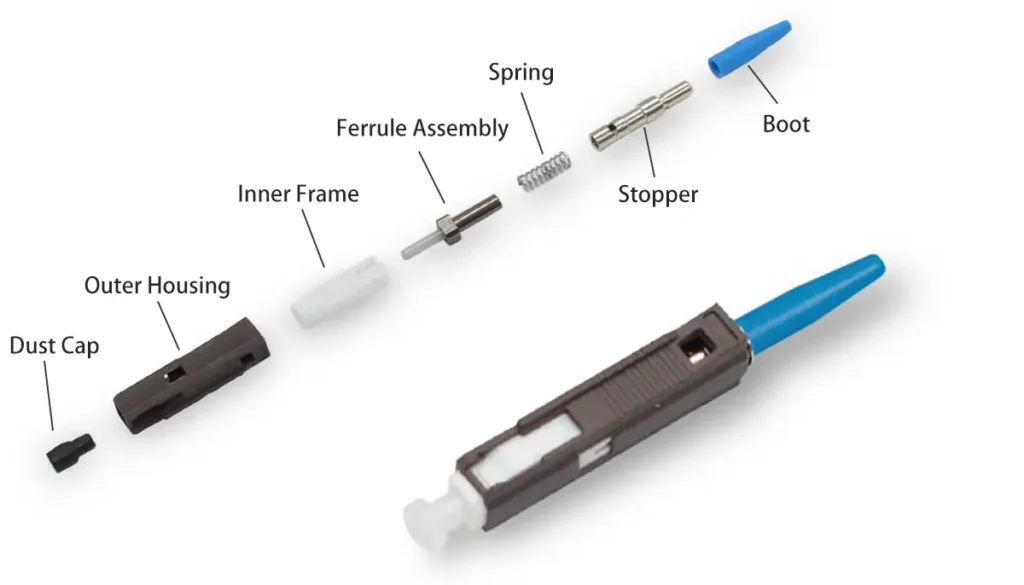

SC (Subscriber Connector)

Figure1-2: 0.9/2.0mm SC Fiber Optic Connector exploded view

As illustrated in Figure 1-2, the SC connector has a relatively simple structure. In practice, the footprint of one SC connector is roughly double that of an LC connector—meaning two LC connectors can fit in the same panel space as a single SC.

The SC connector, developed by NTT, uses a 2.5 mm ferrule and a push-pull design. It was one of the earliest standardized connectors and remains widely used, especially in telecom and CATV applications. Although larger than LC, SC is valued for its robustness and ease of use.

ST (Straight Tip)

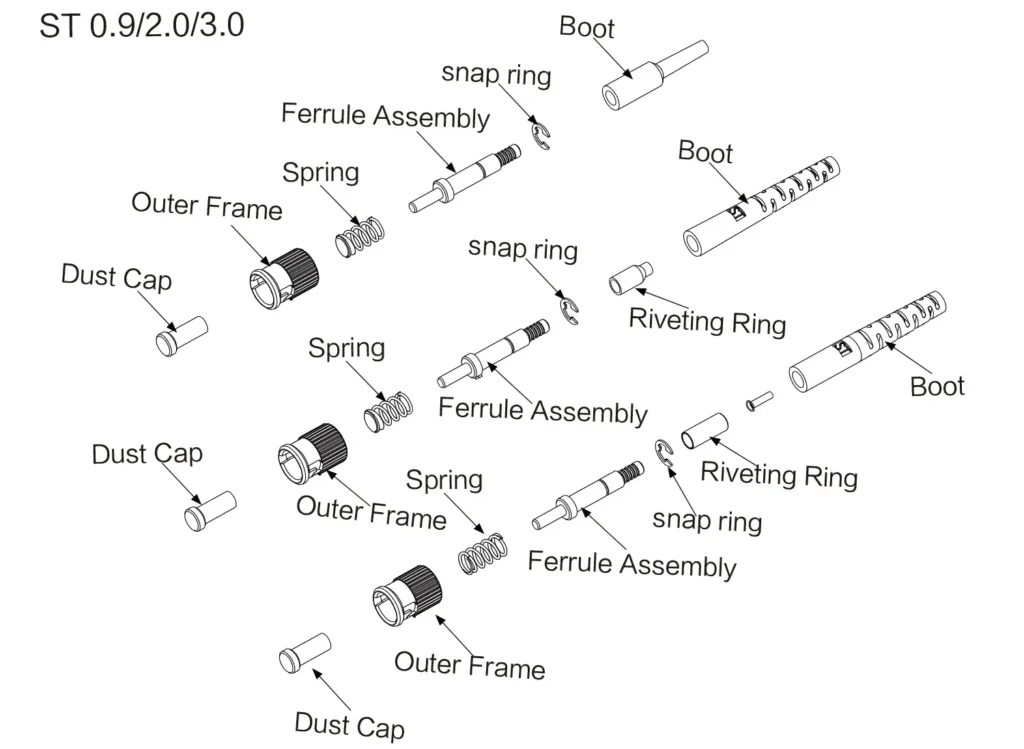

Figure1-3: 0.9/2.0/3.0mm ST Fiber Optic Connector exploded view

ST connectors feature a bayonet-style twist-lock design and a 2.5 mm ferrule. They were widely used in early fiber installations, particularly in LANs and campus networks. While less common in new deployments today, ST connectors can still be found in legacy systems.

FC (Ferrule Connector)

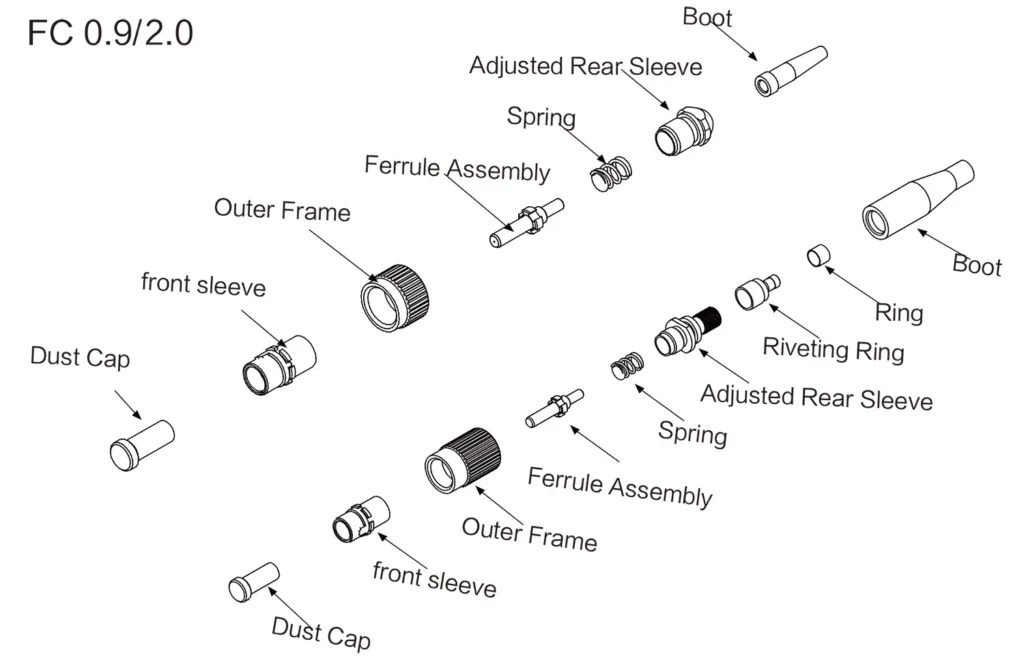

Figure1-4: 0.9/2.0 FC Fiber Optic Connector exploded view

The FC connector employs a screw-on mechanism that provides excellent stability, making it suitable for applications requiring high precision and vibration resistance, such as measurement instruments. Though less common in modern data centers, it remains relevant in specialty fields.

MPO/MTP (Multi-Fiber Push On)

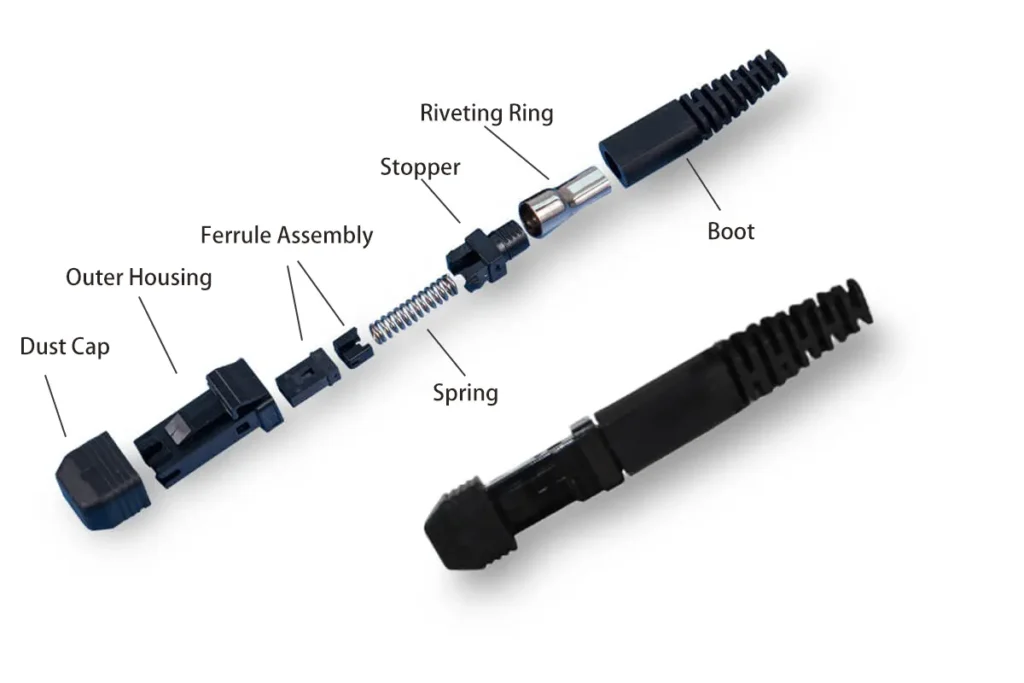

Figure1-5: MPO Fiber Optic Connector exploded view

MPO (and its enhanced version, MTP) connectors are designed for multi-fiber connections, typically 12 or 24 fibers in a single rectangular ferrule. They are essential in high-density cabling systems, especially in data centers where space and scalability are top priorities. MPO/MTP connectors also enable parallel optics for 40G/100G/400G Ethernet.

As shown in Figure 1-5, the MPO connector is composed of multiple precision components that ensure proper alignment of multiple fibers. Since this article focuses on providing an overview of fiber connectors types, a more detailed explanation about mpo connectors can be found in our dedicated guide: [MPO Connector Full Guide: Structure, Polarity, and Fiber Applications]

E2000

Figure1-6: E2000 Fiber Optic Connector exploded view

Developed by Diamond, the E2000 connector includes an integrated protective cap that automatically covers the ferrule when disconnected. This design prevents dust contamination and protects users from accidental laser exposure. It is widely used in telecom and high-performance applications in Europe.

MU

Figure1-7: MU Fiber Optic Connector exploded view

The MU connector is a miniature version of the SC, using a 1.25 mm ferrule like the LC. It is compact and reliable but less commonly adopted compared to LC due to lower market penetration.

Since the MU connector has a small market share and limited usage, this article will not go into further detail.

MTRJ (Mechanical Transfer Registered Jack)

Figure1-8: MTRJ Fiber Optic Connector exploded view

The MTRJ connector is modeled after the RJ-45 design and supports two fibers in one connector. While compact, it has largely been replaced by LC in modern systems due to LC’s superior performance and versatility.

As MTRJ is gradually being phased out in favor of LC, we will also keep the introduction brief.

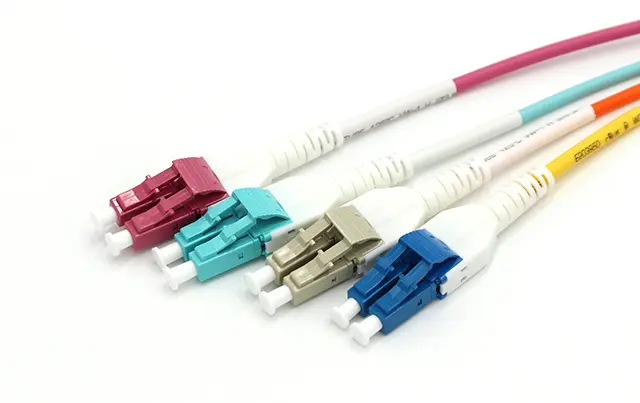

Classification by Design & Performance

Besides the connector types themselves, fiber optic connectors can also be classified according to their design variations and performance characteristics. These factors influence how the connectors are used in different environments and how efficiently they manage space, signal quality, and ease of handling.

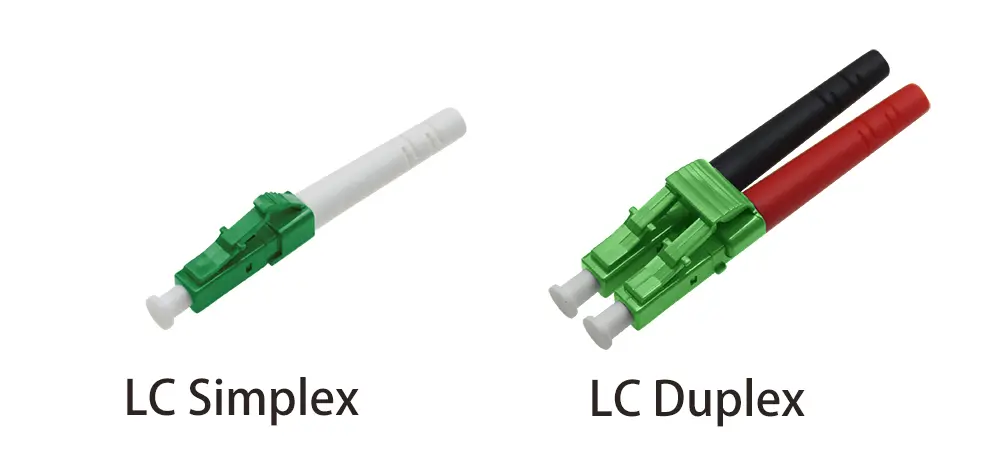

Simplex vs Duplex

- Simplex connectors carry a single fiber, typically used for one-way transmission. They are common in systems where data only flows in one direction, such as certain sensors or broadcast applications.

- Duplex connectors combine two fibers in one unit, allowing simultaneous bi-directional transmission (one fiber for transmit, the other for receive). This design is widely used in telecom and data centers.

👉 Duplex LC connectors are especially popular because they enable high-density deployment without compromising performance.

Uniboot Design

Uniboot connectors house two fibers within a single jacket, significantly reducing cable bulk and improving airflow in high-density environments like data centers. Compared to standard duplex connectors with two separate cables, uniboot designs simplify cable management and reduce congestion on patch panels. Some uniboot connectors also allow polarity reversal, making them versatile for system upgrades.

Connector Polish Types (PC, UPC, APC)

The fiber end-face polishing style is one of the most critical factors affecting signal performance:

PC (Physical Contact): An older standard where fiber ends are polished with a slightly curved surface to reduce air gaps. Rarely used in modern deployments.

UPC (Ultra Physical Contact): Provides a finer surface polish, resulting in lower insertion loss and higher return loss compared to PC. Widely used in Ethernet and telecom networks.

APC (Angled Physical Contact): Features an 8-degree angled end-face, which directs reflected light into the cladding rather than back into the core. This dramatically improves return loss performance, making APC the preferred choice in high-bandwidth and long-distance applications such as FTTx, CATV, and passive optical networks (PON).

👉 In practice: UPC connectors are suitable for short-distance, general-purpose connections, while APC connectors are chosen for precision and long-haul communication where signal reflections must be minimized.

More detailed to check:[Fiber Optic APC vs UPC – What’s the Real Difference?]

Frequently Asked Questions

What is the difference between a fiber optic connector and a fiber optic adapter?

A connector is the device attached to the end of an optical fiber to enable connection, while an adapter is a coupling device that aligns and joins two connectors together. Simply put, connectors are the plugs, and adapters are the sockets.

What is the difference between UPC and APC connectors?

UPC (Ultra Physical Contact) connectors have a flat or slightly curved polish, while APC (Angled Physical Contact) connectors are polished at an 8° angle. APC connectors offer much better return loss performance, which makes them essential for long-distance, high-bandwidth, and sensitive applications such as CATV and PON. UPC is sufficient for short-distance, standard telecom or data center usage.

How many times can a fiber optic connector be plugged and unplugged?

The durability of a fiber optic connector depends on its design and quality. Standard connectors are typically rated for 500–1,000 mating cycles, while higher-grade or hardened connectors can withstand even more. However, frequent reconnections increase the risk of contamination, so proper cleaning and inspection are necessary.

How do I choose the right fiber optic connector for my project?

It depends on your application, density, and performance requirements:

- For data centers, LC or MPO is usually preferred due to high-density needs.

- For FTTx and telecom, SC and APC connectors are common.

- For specialized instruments, FC connectors may be required for their stability.

Always consider connector type, polish style, and cable management needs before selecting.

In Summary

Fiber optic connectors may seem like small components, but they play a critical role in ensuring the reliability, speed, and efficiency of optical communication systems. From the widely used LC and SC to high-density MPO solutions, each connector type is designed to meet specific demands in telecom, data centers, and beyond.

The right choice of connector—whether simplex or duplex, UPC or APC—can directly impact network performance and long-term scalability. As fiber continues to replace copper in global networks, the importance of precision-made connectors will only grow.

At YingFeng Communication, we have over 20 years of experience in manufacturing fiber optic connectors, with a production capacity of 100 million sets per month. Our products are fully compliant with GR-326 standards and trusted by global customers for OEM and ODM solutions. If you’re looking for a reliable partner to support your fiber optic projects, YingFeng is here to provide the expertise and quality you need.